Harmonic Pulse Testing as a Monitoring Tool for Enhanced Geothermal Systems

What is Harmonic Pulse Testing?

Harmonic pulse testing is a technology that has similar capabilities as regular well testing. It intends to determine hydraulic parameters such as transmissivity, wellbore storage, skin and storativity. A train of equally long pulses in injection rate or production rate is applied to the reservoir by switching the rate. The pressure is monitored in the pulser well, or in a nearby observer well.

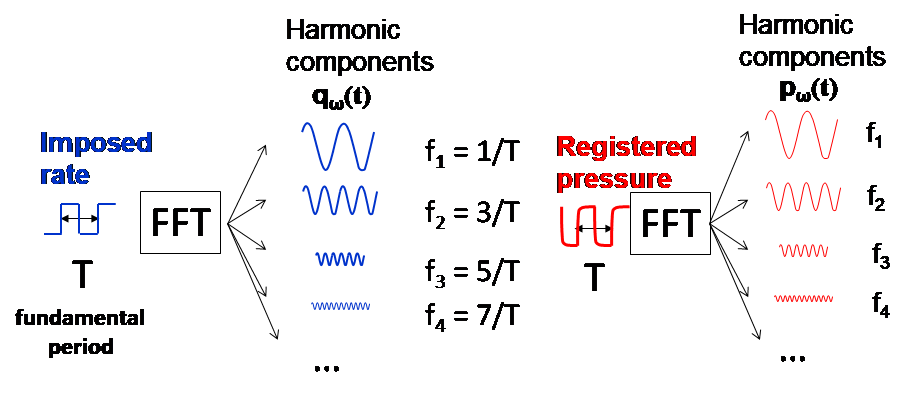

A train of pulses is a combination of many frequencies, therefore a pulse test is a simultaneous test of many harmonic components. The interpretation is based on the presumption that a harmonic signal in the injection rate yields a harmonic signal in the pressure, and that different frequencies react independently. With a Fast Fourier Transform (FFT) algorithm, the frequency information can be extracted from the time traces as shown in Figure 1.

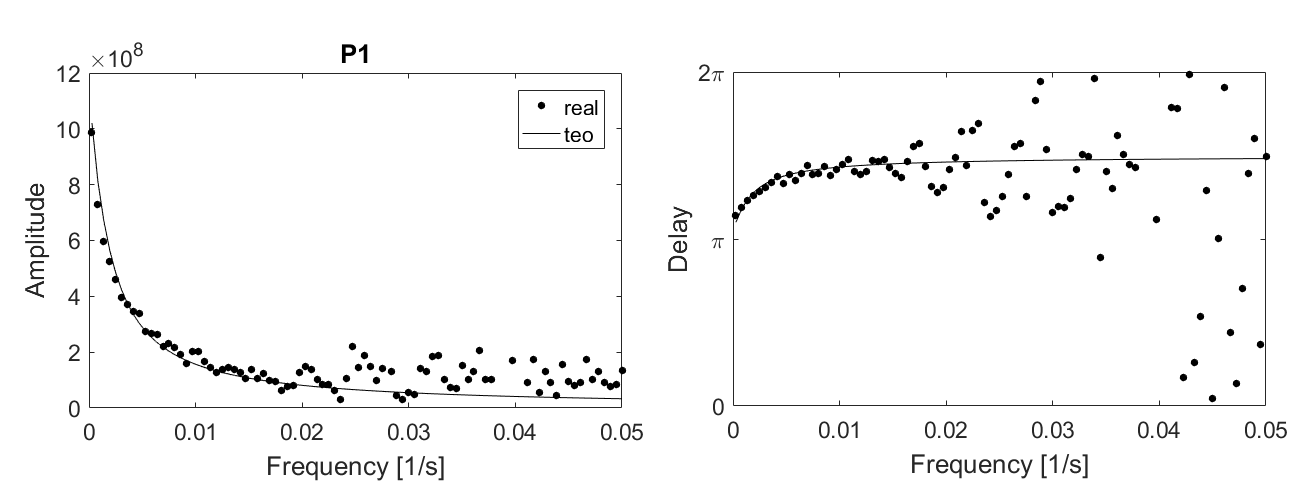

The interpretation involves the evaluation of the pressure response to the rate input. This is done for every frequency present in the two spectra. The response has two components: the amplitude quantifies how large the absolute value of the response is with respect to the input; the phase quantifies the delay of the response with respect to the input. Theories have been developed that resolve this relationship in terms of the model parameters: transmissivity, skin, wellbore storage, and reservoir storativity. A simultaneous matching of measured responses to calculated responses by varying these input parameters yields the required values. An example is given in Figure 2; documentation can be found in Fokker et al. [2017].

Figure 2: Example response (amplitude and delay) of a harmonic pulse test in Pohang. More than 20 frequencies (up to 0.018 s-1) give useable response and a theoretical response can be matched by adjusting the reservoir parameters. The match results in estimates for permeability and wellbore storage parameters.

Why applying pulse testing?

In comparison to well testing, pulse testing employs a number of pulses rather than a single one. Therefore, it requires more time. However, there are two important advantages. First, the deployment is simple. A regular pump must be switched at well-defined moments while rates and pressures are monitored. This can all be done with standard equipment. Second, harmonic pulse tests can be performed while other operations are ongoing. This saves expensive non-productive time. Even more important, it facilitates the use of the technique as a monitoring tool during operations. As an example, the effect of stimulation can be assessed in real time by superposition of a pulse on top of an injections schedule. This way, the injectivity during different background injection rates can be followed.

How to conduct pulse testing?

The first operational decision, prior to the application of pulse testing, is the determination of the pulse durations, i.e. the fundamental period. This parameter depends critically on the expected reservoir properties and on the pulse test configuration. Expected values for the parameters can be used with the theoretical relationships to determine for what values reasonable signals can be expected. This is also related to the choice whether monitoring is employed in the pulser well only or also in an observer well.

The number of pulses must be sufficient to obtain the frequency information. Usually, 7 to 10 pulses suffice.

To be able to obtain a maximum amount of useable frequencies, high-quality data are required. The least critical component of the data is the : it should be in the order of 5 to 10%. More important are timing parameters. Firstly, the sampling rate should be high enough – for instance, for one-hour pulse durations, a sampling rate of 5 seconds. or higher is preferred. Secondly, the moment of switching between rates should be controlled to within 2 or 3 times this sampling rate. Otherwise, higher frequencies will not appear clear enough in the frequency spectrum. Finally, the clocks for sampling the rates and the pressures should be synchronized to the same precision. A mismatch has a direct impact on the delay, with linearly increasing effect for increasing frequencies.

References

P.A. Fokker, E. Salina Borello, F. Verga and D. Viberti, 2017. Harmonic pulse testing for well and reservoir characterization. Paper SPE-185815-MS in Proceedings of SPE Europec, 12-15 June 2017, Paris, France [doi.org/10.2118/185815-MS].