Hydraulic, chemical and thermal stimulation

What is stimulation?

Stimulation in general is a method to enhance well productivity or injectivity within different types of reservoirs ranging from sediments like sandstones and limestones to crystalline rocks like granites and basaltic rocks. Based on the type of reservoir with its individual environment hydraulic, thermal or chemical stimulations are performed. Stimulation treatments were developed for the petroleum industry to enhance oil and gas recovery, but were adapted to geothermal reservoir developments in recent years to enhance the extraction of heat.

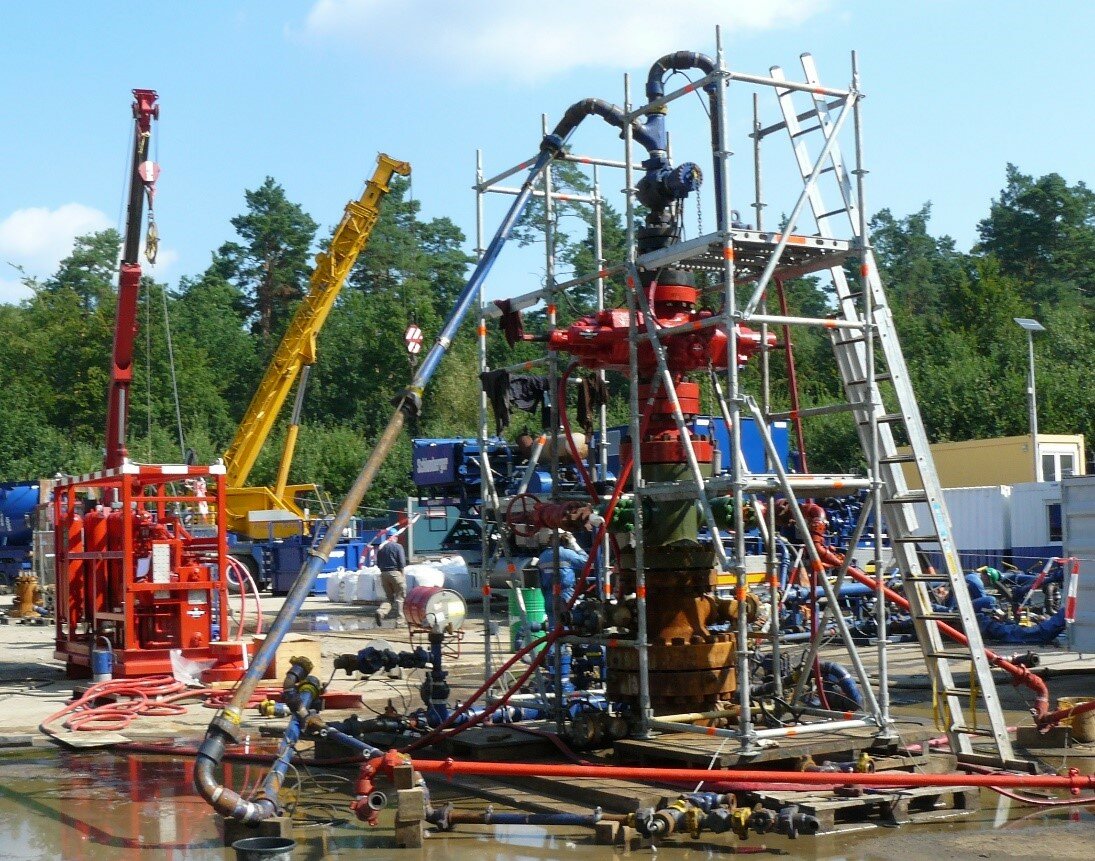

Figure 1: Modified well head for hydraulic stimulation treatments and hydraulic tests.

Hydraulic stimulation

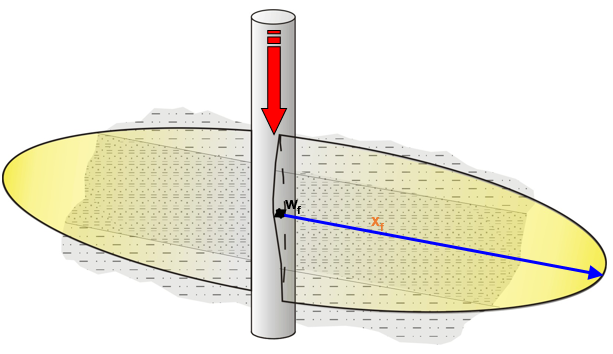

Hydraulic stimulation can be described as injection of fluids at high flow rates into a reservoir to develop new fractures or reactivate and enhance the hydraulic performance of existing fractures. The basic concept of hydraulic stimulation includes different failure processes of fracture initiation and propagation. This can be summarized by different failure criteria and loading modes, i.e. tensile failure (mode I) or failure in shear (mode II). Research on hydraulic stimulation confirmed that shearing rather than tensile fracturing is the most effective process to develop a fracture network suitable for geothermal heat extraction in the crystalline basement. Natural joints, favorably aligned with the principal stress orientations, fail in shear at lower pressure than the pressure required for tensile fracturing. As a consequence, formations with high differential stresses, and hence a high shear stress, should be best candidates for hydraulic stimulation in low permeable rock. In case of primarily tensile failure (mode I), the sustainability of generated fractures depends on the residual opening of a fracture after fluid pressure release. This can be enhanced by the transport and placement of proppants to support the long-term opening of the fracture. This approach is state of the art in the oil and gas industry to overcome near well bore damage and has been applied for shale gas exploitation, but so far was rarely used in geothermal wells.

Figure 2: Fracture generation due to injection of water (wf = fracture width; xf = fracture half length).

Chemical stimulation

The term chemical stimulation refers to the injection of fluids with chemical additives into the geothermal target formation. It is performed to overcome formation damage in the rock matrix as well as inside existing fractures and fissures leading to dissolution of certain minerals and thus increasing the hydraulic pathways in the rock and enhance the permeability.

In contrast to other stimulation techniques, chemical stimulation affects mostly the near borehole volume up to several meters from the well; fast reaction kinetics associated to the high reservoir temperature are leading to rapid acid degradation. However, in fractured rocks or karst formations acid solution can react further through existing flow paths.

Generally, three basic types of chemical stimulation can be distinguished: Acid Washing, Matrix Acidizing and Fracture Acidizing. They are differentiated by pumping pressure and therewith penetration depth. Acid Washing aims at cleaning the wellbore and dissolving scales at the casing or drilling related damage at the formation face.

Thermal stimulation

For thermal stimulation of a well, cold water is injected below the fracturing pressure over a certain time period, generally a few days to weeks. Due to the low temperature of the water compared to the temperature of the rock, the stress in the rock changes, leading to stimulation of natural fracture networks or initiation of new fractures. Thus, the effect of thermal stimulation is very similar to the effect of hydraulic stimulation.

Thermal stimulation or thermal fracturing occurs in many cold-water injection wells and often an increase in injectivity with decreasing temperature of the injected water is observed. This is probably due to initiation and growth of thermal fractures near the well bore and higher weight of the fluid column.

Multi-stage and cyclic stimulation concepts

Horizontal multi-stage hydraulic fracturing is the process by which multiple fractures are created along a horizontal section of the wellbore in a series of consecutive operations. It is a well-established practice in the oil and gas industry and can be seen as a key technology enabling the development of enhanced geothermal systems. It provides better access to reservoirs, since horizontal wellbores allow for much greater exposure to a formation to develop a downhole heat exchanger with an appropriate size for extraction of heat. The individual stimulation is carried out stepwise in isolated intervals. This can be achieved by perforating the intervals of interest. One crucial aspect is the right distance between the perforation intervals to avoid any interference. This depends on the rock properties and the state of stress and needs to be simulated in advance. In geothermal, multi-stage shearing through the pre-existing fractures is the main mechanism and swellable packers are considered to be used instead of perforations.

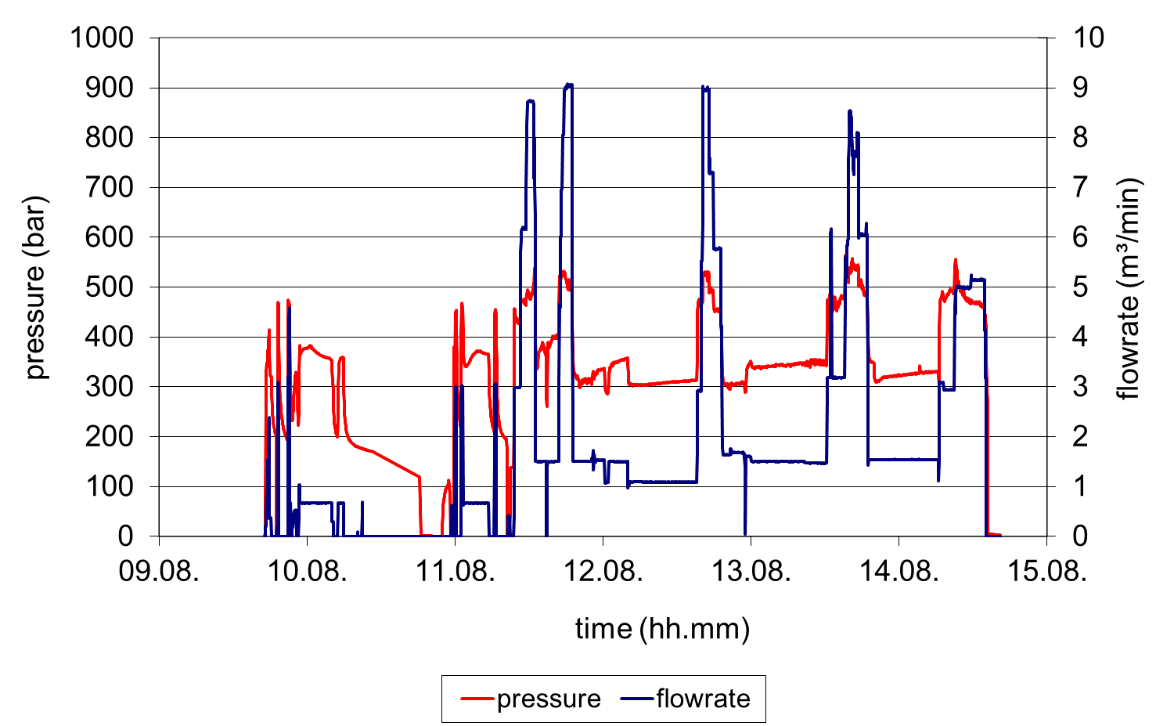

Furthermore, suitable stimulation schemes may include cyclic stimulations with varying flow rates (so called soft/fatigue stimulation) to reduce the risk of unwanted seismic events with large magnitudes.

All scenarios have to be evaluated regarding the site-specific geological requirements to optimize the performance of the reservoir for geothermal heat extraction and simultaneously reduce the risk of unwanted seismic nuisance and environmental impact.

Figure 3: Waterfrac treatment with cyclic variation of flow rate from the EGS site in Groß Schönebeck, Germany (from Zimmermann et al., 2010).

Why is it important?

All stimulation designs have in common that they are necessary to enhance the productivity (or injectivity) of low permeability geothermal reservoirs, which are not economically viable, i.e. enhance the flow rate performance to improve the heat extraction from depth.

Hydraulic stimulation treatments can generate new fractures, which act as artificial fluid pathways and improve the performance of the reservoir. Matrix acidizing treatments are designed to remove near wellbore damage, primarily associated with plugging of pores as the consequence of drilling, completion, stimulation or operation. Thermal stimulation has been actively used in high enthalpy geothermal fields in volcanic and metamorphic settings to increase the productivity of wells. The injection of cold water leads to a cooling of the rock in the near well bore environment, or adjacent to existing natural or induced fractures. The value of this thermally induced tensile stress depends on the shape of the cooled region, the thermal and elastic rock properties, the difference between the down hole and surface water temperatures, as well as the injection rate.

How is it performed?

All stimulation treatments have in common that fluids are injected into geothermal reservoirs. In case of a hydraulic stimulation water injection under high pressure is performed to produce or open preexisting fractures. It is performed by injection from top of the well (bullheading) or by injection into a reservoir segment via a workstring and packers to straddle the targeted interval (selective stimulation).

Chemical stimulation can be performed in acid soluble rock formations such as carbonate rocks. Type and composition of the acid is determined by the mineralogy of the rock to dissolve the damaging material. Along with the mineralogy of the rock and the location of the target minerals the type and severity of formation damage play an important role in determining the type and composition of the acid being used. Typically, the acid is injected through coiled tubing together with corrosion inhibitors to avoid reaction with any equipment or casing on the way to the target formation.

Risk assessment

Analyzing induced seismicity to minimize the risk of felt seismic events, which may accompany hydraulic stimulation treatments, must be carefully taken into account to maintain public acceptance for geothermal site developments.

Therefore, a risk assessment in terms of a slip tendency analysis to analyze the reactivation potential of existing continuities or failure analysis to estimate the potential of rock failure is highly recommended prior to a stimulation treatment. The minimum requirement of such an analysis is the best knowledge about the stress field, the hydraulic-mechanical rock properties and the stimulation treatment parameters, which will alter the in-situ reservoir conditions in term of pressure and temperature field.

The risk assessment provides guidelines to establish a site dependent procedure known as traffic light system (TLS) to take adjusted actions according to the occurrence and intensity of induced seismicity.

Reviewers

Ki-Bok Min, Seoul National University

Clément Beaujard, és-Géothermie

Frédéric Guinot, Geo Energie Suisse

Literature

DiPippo R (Ed) (2016) Geothermal Power Generation – Developments and Innovation, Woodhead Publishing Series in Energy: 97, Elsevier

Economides MJ, Nolte KG (2000) Reservoir stimulation, 3rd ed. Wiley, United Kingdom.

Yew, C.H., 1997. Mechanics of Hydraulic Fracturing. Gulf Publishing Co., Houston, TX, USA.

Zang A, Stephansson O (2010) Stress field of the earth’s crust. Springer, Berlin.

Zimmermann G, Moeck I, Blöcher G (2010) Cyclic waterfrac stimulation to develop an Enhanced Geothermal System (EGS) – Conceptual design and experimental results, Geothermics, 39, 59-69.